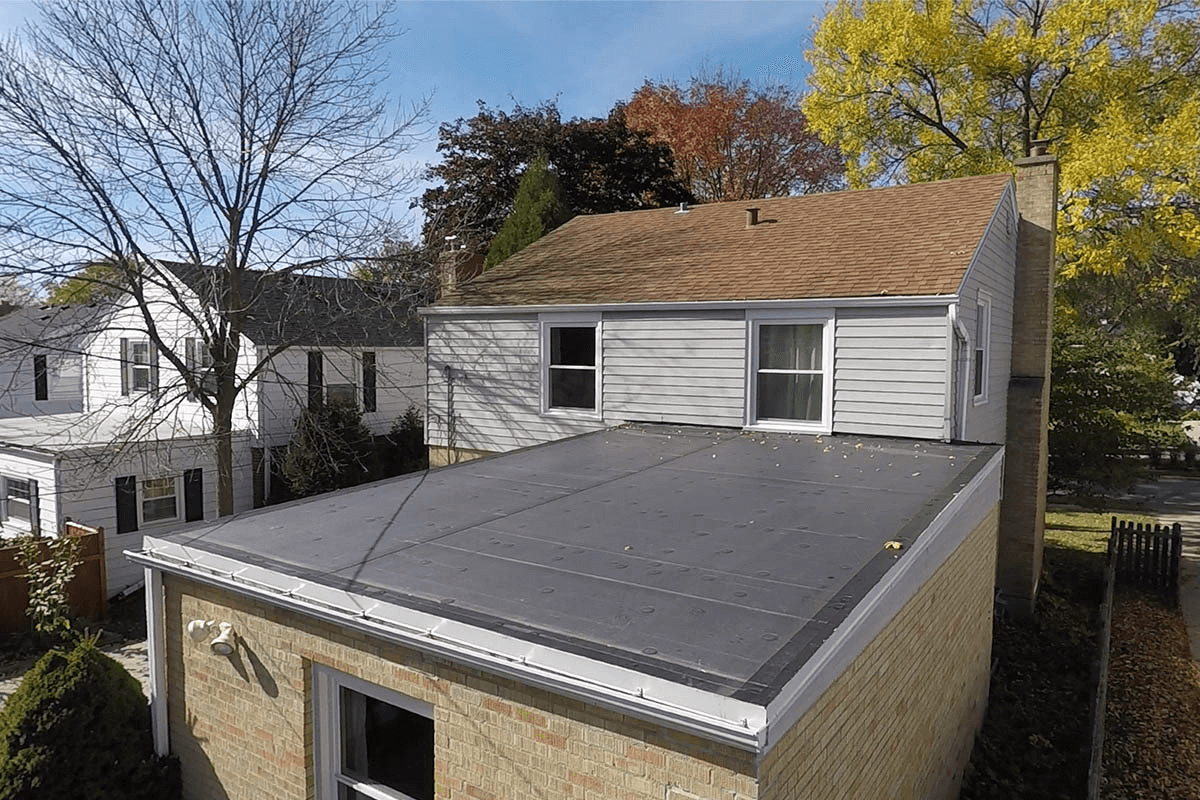

Since the 1960s flat roofs have evolved, and now, you no longer have leaky roofs that are too expensive and hard to maintain. Currently, flat roofs require low maintenance. Additionally, they can last as long as 15 years with a trouble-free life. With EPDM roofs, some manufacturers can guarantee a life expectancy of 50 years. As such, this rubber roof is a great choice for residential and commercial roofs.

Just like any roofing material, if the components are not properly installed, problems are likely going to occur. The same can be said for EPDM roofs from Rubber Roofing Direct. Planning and preparation are the keys to success with EPDM roofs. Here are the top 5 tips to help you avoid flat roofing snags.

1. Cleaning

Make sure the freshly installed or existing deck is 100% clean of chippings, dust, raised fixings and sharp objects. If not, they will show up under the EPDM membrane and prevent the glue from bonding properly. Make sure all decking is dry and fastened adequately.

2. Proper Installation

Next, you need to unfold the EPDM membrane and lay it in position. Make sure it hangs over the roof edge by at least 75mm or 3 inches then turn up the walls by 200mm or 8 inches. Leave it there for about 30 minutes to help remove any potential creases. Hiring a local roofing company will help if you are having trouble with the ins and outs of self-installation.

3. Use Adhesive

Next, you need to apply and approved and strong bonding adhesive (preferably solvent-based), specifically designed for this process. It needs to be approved by the EPDM supplier. Additionally, you can use an approved WBA deck adhesive. Choose one that can be roller applied to the substrate.

If you choose the solvent adhesive, it needs to be applied to the underside of the sheet. The EPDM membrane needs to be in position properly sized and without any creases before applying the adhesive. The solvent-based adhesive needs to flash off to prevent blistering underneath the membrane.

4. Rolling Back

Now you can roll back the EPDM coated with the adhesive onto the deck where you had also applied the adhesive. Work slowly and evenly to reduce wrinkles. If you attach the EPDM incorrectly to corners, drains, walls and pipes it may allow water to get in. Seal the penetrations and corners with EPDM primer or moldable tapes (pressure sensitive) to seal the potential openings.

5. High-Quality Roof Perimeter Trims

Finally, you need to make sure the roof perimeter trims have high-quality finishing to complement the EPDM. They can be made of uPVC or plastic-coated metal.